|

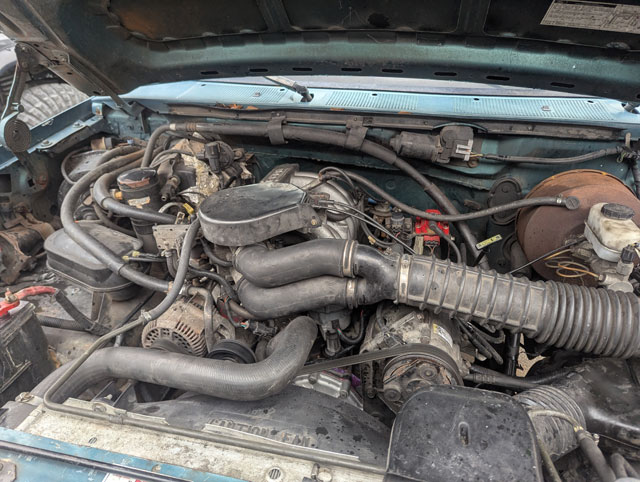

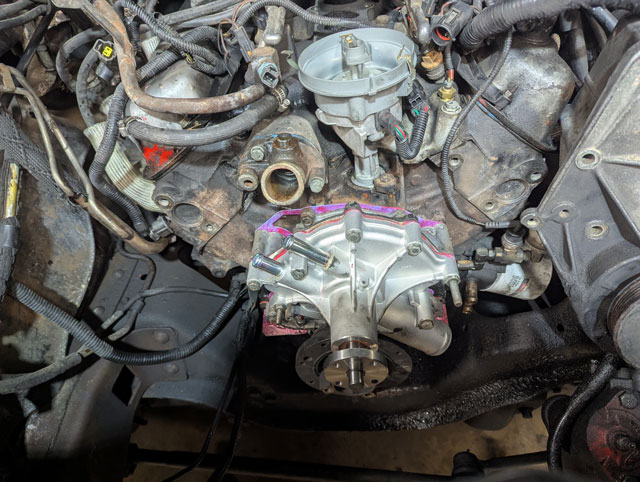

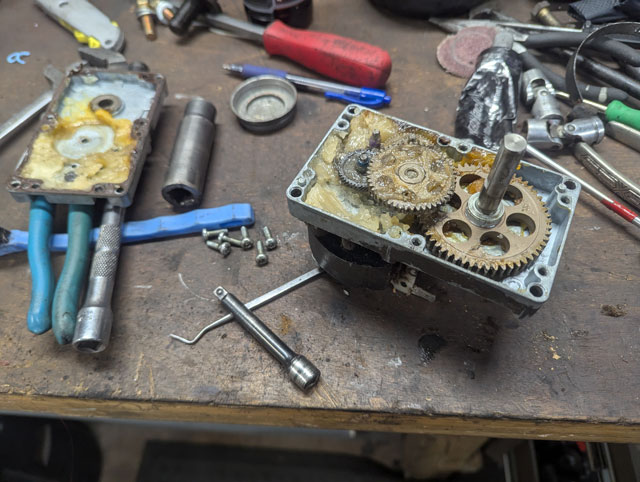

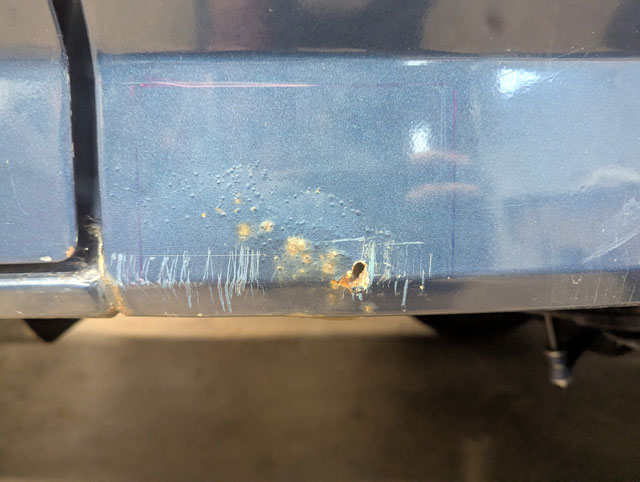

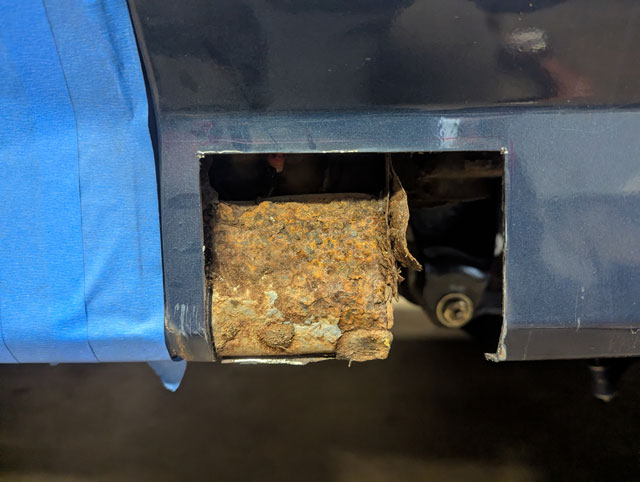

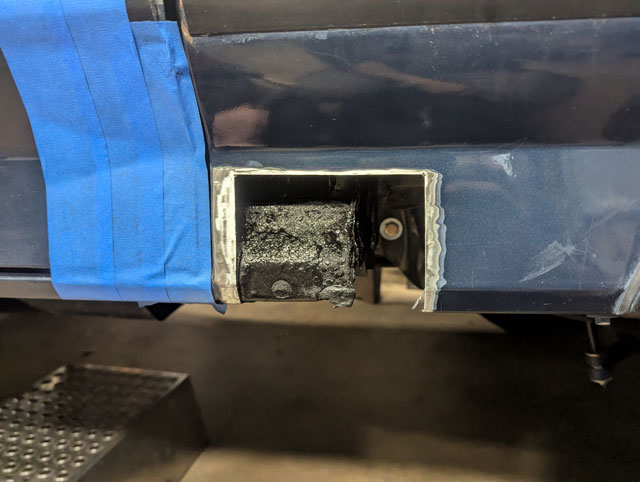

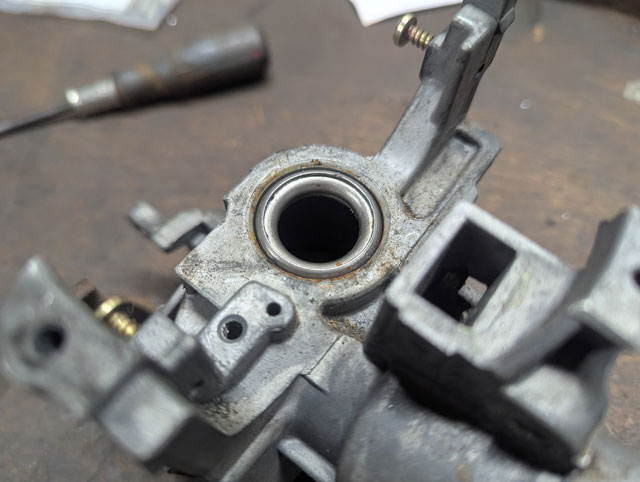

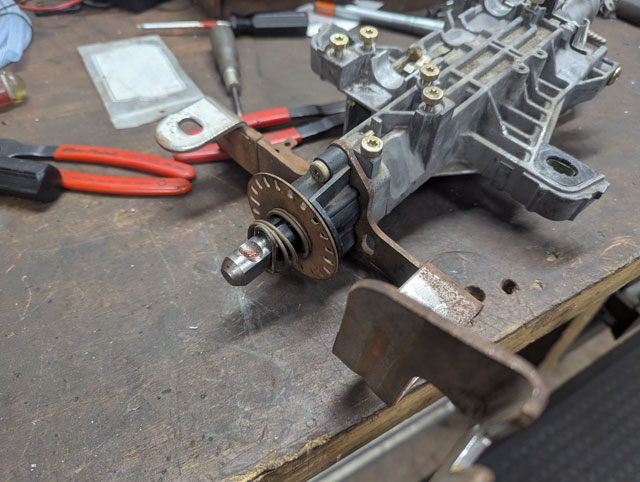

The new coolant manifold showed up last night Wasnt expecting it to come w/o the threaded fitting, so i had recover that from the old manifold ...installed... ...and finally done! Me and the little dude took it to the carwash to get the road salt off, just in time for it to snow again tonight and all next week ...oh yeah, and i still havent found my damn ratchet!! Intake off intake on stove fixed ...and engine back together! ...or not Stem rotted out and snapped off in my hand. Cant get one til Friday, and the plenum and distributor will have to come back off to replace it. Still dont know where my ratchet is either. Green one is back in the garage again. Timing cover started leaking at the coolant feedthru to the block Figured its been ~110k since i had the timing cover off last, so id throw a pump & chain at it while i was in there Going back together It was at this point that the drive motor for the lower augur in the pellet stove died Still waiting on parts to fix that, but moving on, i finished putting the cooling system back together and decided to pressure test it before going any further. Then i found a leak on the passenger side of the intake where it meets the head. So as of this morning the intake is off: Tomorrow im going to clean up all the surfaces are start putting it back together. Spent a good half hour today looking for my 1/4" ratchet w/ 7/16 deep socket that i apparently misplaced yesterday. Gone forever it seems. Already put 40k miles on the Thunderers! They were decent for a cheap mud terrain, but as the tread got pretty low their rain/snow performance suffered. So its time for a new set of tires. Enter one set of Falken Wildpeak AT4ws! With a 60k mileage rating, and 235k on the clock, if we get the advertised mileage out of these tires, we'll be pretty close to 300k miles by the time we need a new set. Time will tell! First up, had to remove the disintegrating rear window seal New seal: ...and installed! Ok, back to the main project. 3rd patch panel made ...tacked... i was in the zone, so now its all welded, ground, and the first round of body filler applied Just slapped some primer on it, so we'll see how it looks tomorrow, maybe ill be able to get some paint on it! Finally got paint, and some time to lay it down: So this side is now done! One last ting i wanted to do before turning it around, is replacing this very flat door seal Ordered a set of door seals from Dennis Carpenter Replaced the door seal, and then turned the bronco around in the garage. Went to put the tailgate down, and the upper glass door seal fell out! Turns out it was so old it turned to plastic and was crumbling in my hand. So now ive got rear window seals on order But enough distractions. Weve got one more rough spot in the body to deal with: All cut out and prepped: Hopefully this week i can get this patch done, along with the rear window seals, and then i can finally move on to rebuilding that ZF i bought way back when! The first patch panel is now welded in Moving to the other side of the wheel arch, we have to deal with this as well Cut open to expose the typical corner rot I cut that crusty piece out to expose nice clean steel for the main structure, so we caught it in time (pic missing) Bending up the next patch panel... ...and its in! Still waiting on paint, so im going to get these prepped and primed so once the paint shows up i can just paint em and move on to the other side of the bronco. Back at it With the column in the 96 bronco fixed, we can now get back to the real reason we pulled the 90 into the garage...body work! First up weve got to fix this spot The offending material And the hole, cleaned and prepped for a patch panel The little dude helped me set up the sheetmetal brake ...and bent his first piece of steel! Ok, back at it. Upper bearing replaced Lower bearing replaced, shaft installed, and sleeve/spring/snapring installed Tilt mechanism reassembled Lower bearing housing: and installed, along with the lower column mount & retainer Column going back in... ...and done! |

Categories

All

Archives

February 2025

|