|

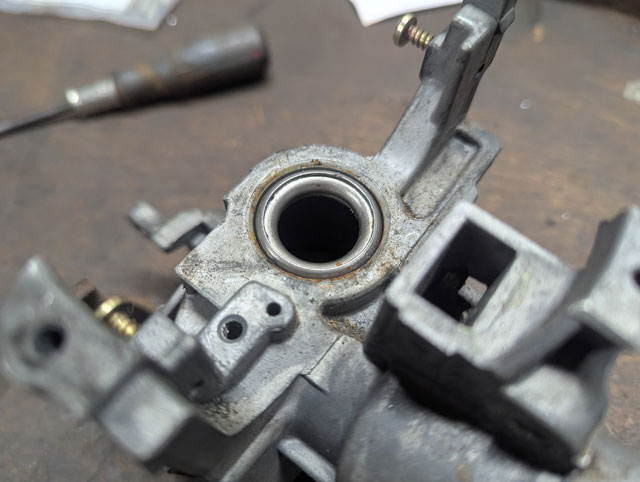

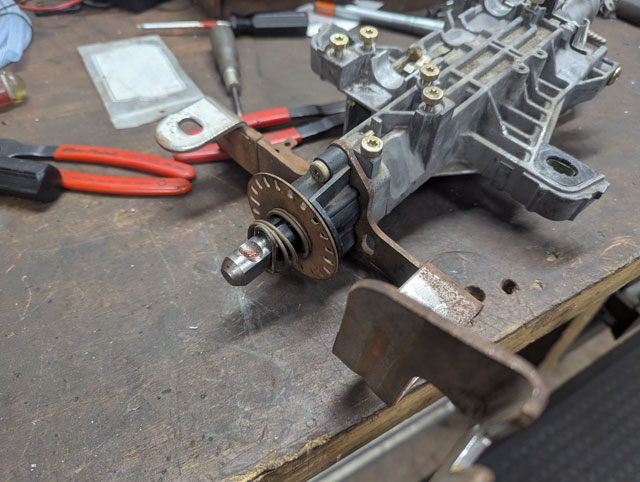

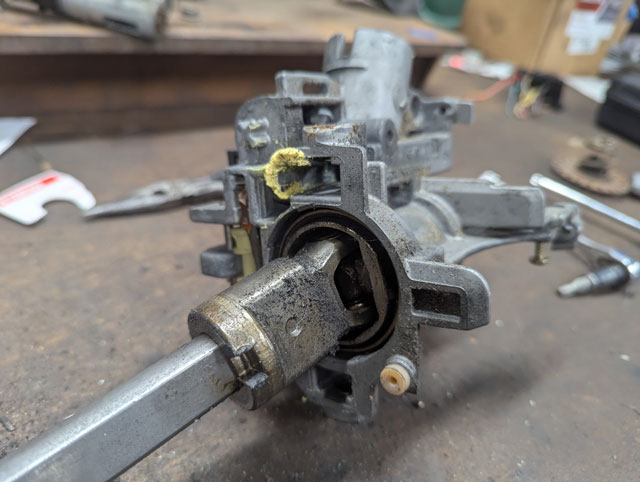

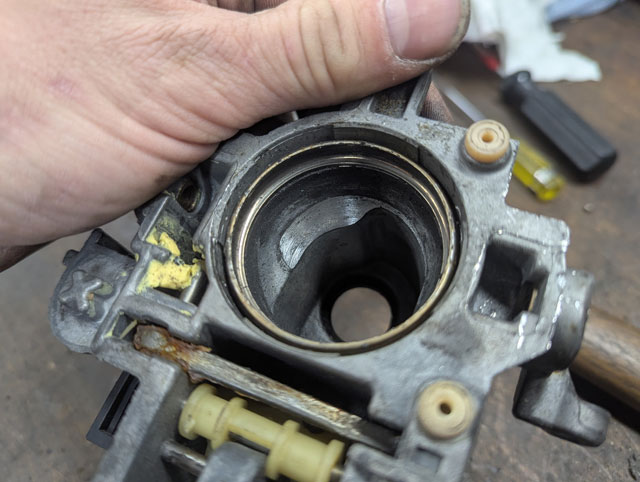

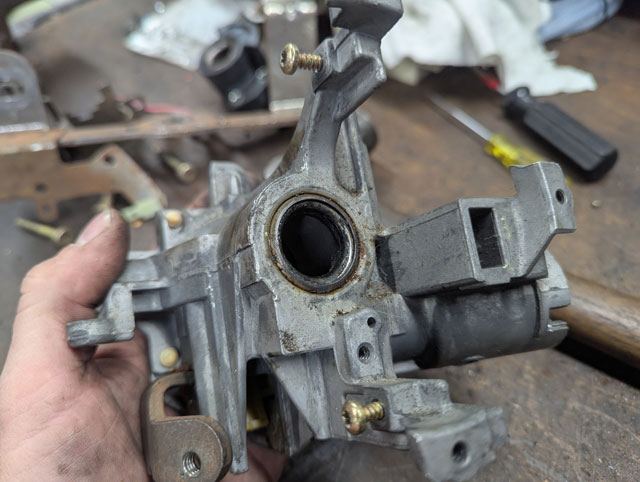

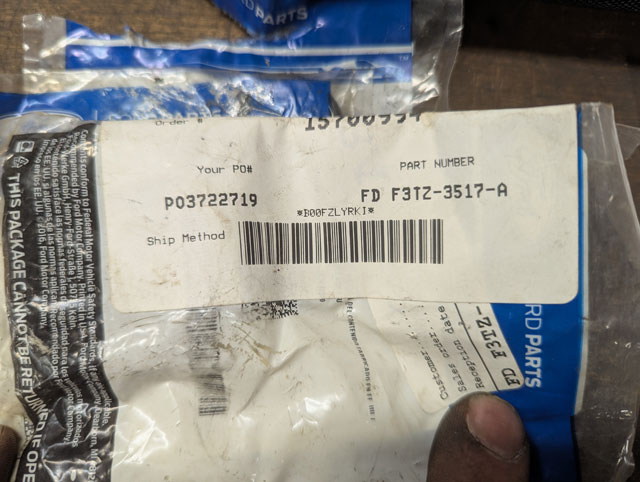

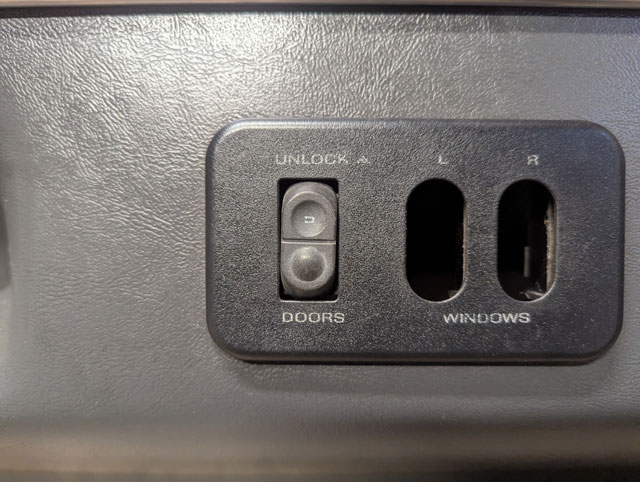

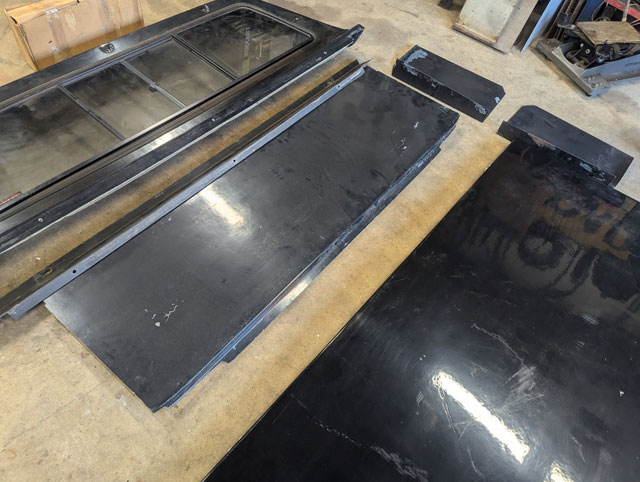

Ok, back at it. Upper bearing replaced Lower bearing replaced, shaft installed, and sleeve/spring/snapring installed Tilt mechanism reassembled Lower bearing housing: and installed, along with the lower column mount & retainer Column going back in... ...and done! So naturally, as soon as i finish a repair on one bronco, another desires attention Felt a weird clunk when turning the other day, and i immediately knew what happened. One of the steering column bearings had failed. So the column is now out: Just the process of getting to this point bearings have been falling out, so we caught it just in time, before the column got damaged too badly The large tilt bearing has failed With the shaft out you can see part of the bearing race was still on the shaft Bearing has completely disintegrated I had to drive it for a couple days after it happened, and you can already see wear on the inside of the housing The small upper bearing looks ok, but its not Looking at the other side, you can see the race is split Unfortunately, the ujoint in the shaft is also worn out. Fortunately, i had a few spare columns in the shed Picked the junkiest one and stripped it down for the shaft. Fortunately, this one has a ujoint that is nice and tight. So i rummaged thru the cabinet, and found a full set of bearings, and an upper serdive kit as well! So we're good to on parts to rebuild this column Lower bearing (also the same as the upper bearing) Large tilt bearing And then thsi is the upper bearing service kit, which includes a bearing (not pictured), tapered sleeve, bushing, spring & snap ring Later in the week we'll get this thing slapped back together good as new! Weve got the '90 in the garage for some repairs Troubleshooting the door locks, it seems the drive door lock switch has a burned contact. Took it apart and cleaned it but i cant get it to work any more. Did a search on line, and Dorman makes the power window switch, but not the door lock switch. Of course, they make them for the 92-97 trucks, but once again theres no love for the Bricknose trucks. So lets see what we can do. I dug out some spare parts; heres a spare driver door switch panel for a 87-91, and a passenger door switch panel for a 92-97: At first glance, the 87-91 door lock switch has a very similar footprint to the 92+ switch. Even the alignment pin is the same. So this is promising. It even plugs right into the socket! And the door locks work properly as well It does look kind of dumb in the older door panel though So i popped the covers off both switches and aside from the rocker theyre basically identical, which means we can swap the old squared-off rocker onto the newer switch body ...and done! So this was actually a pretty easy way to fix the door locks, and since you can get replacement switches for the 92+ trucks, now the next time i have a switch fail ill just grab a brand new 92+ switch and swap the rocker over, instead of trying to get the contacts in the old switch cleaned up and hoping itll work. Ok, were back at it. First up, adding a seal to the header I made some simple spacers for the bolts that hold the header in place, so when you torque them down they wont deform the fiberglass. Time will tell if this was a good idea or not. With that done, the header & bulkhead can now be installed: The lower bulkhead leaves a gap at the sides that i dont like, so i made filler panels to seal it off Those pieces then got tack welded to the original side panels to make assembly easier How it looks (prior to weatherstripping) And the completed panels now fully installed, and bolted to both the b-pillar and bulkhead. SPeakers are installed too, which officially completes the cab enclosure Moving on to the back, the tonneau simply bolts to that rail up near the header. It has studs for struts on the lid, and i grabbed the longest ones i could find an Autozone, application unknown, and installed them! The bottom end is some universal strut mounts i got from Amazon, with some Ford sheetmetal screws i had laying around holding them in place. By pure luck the struts are perfect; they lift the lid nice and slowly and hold it up there just fine. Out back at the tailgate i have installed the catches for the latches. I needed bump stops, and it just so happens that OBS Ford hood bumpers are the same size (6mm) as the older bronco's hardtop bolts, so i just threaded a pair right into the existing captured nuts in the body: And......thats it! Installed! I was at Rausch Creek yesterday with a cool group of rigs: Thats Joe (from Bock's Garage) powerstroke bronco in the background. The Centurion was owned by a buddy of his (also 7.3), and then their buddy showed up with this monster Cummins powered jeep on Axletechs: Not too many pics taken from the trip but lots of video. Stay tuned... Unloading this morning: All the parts: This is a half cab/tonneau conversion kit from the (now) defunct Creative Products. Here's an old screenshot from the ad they used to have on their website: Theyre fairly rare these days, altho i still see one popping up now again. This one seems in great shape, like it either was never fully installed, or only installed once or twice. I got a box full of weather stripping (still missing some), no hardware and no instructions. Sent a pic of the pieces laying in the garage to a buddy and he simply replied "im on my way". So we got to work removing the hard top: Poser pics (i dont actually have any topless pics of the truck since i finished it!) Side panel, encloses the cab. If you look closely you can see i have laid out a hole to cut in it, so i can reinstall the rear speakers ...and this is how the lower header fits up: Unfortunately, this is where progress ended. The top half bolts into the original captured nuts for the hard top, but the screws need to be almost 1" longer, and we couldnt find 6mm bolts that length in any of the hardware stores we went to. So we cleaned up and put all the parts back in the garage, because i needed to pack the truck and get it loaded up for a wheelin trip tomorrow. We'll revisit this next week once i have longer hardware. So i tossed all 4 injectors into the parts washer and let em soak for a few days (ok maybe a week) From there i began the process of disassembling and cleaning them: Pulling the nozzle apart, you can see there was still grime and buildup inside them All 4 injectors stripped down You can see that the 4 individual injectors have worn into each other differently, so ive made a conscious effort not to mix and match parts between each injector After full cleaning (and testing each nozzle to see if all 4 ports in each nozzle spray), i have begun the reassembly process: ...and all 4 are now done! So nothing left to do now, but get these things slapped in, get the fuel system bled again, and it should finally roar to life! Here's hoping! |

Categories

All

Archives

February 2025

|